Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

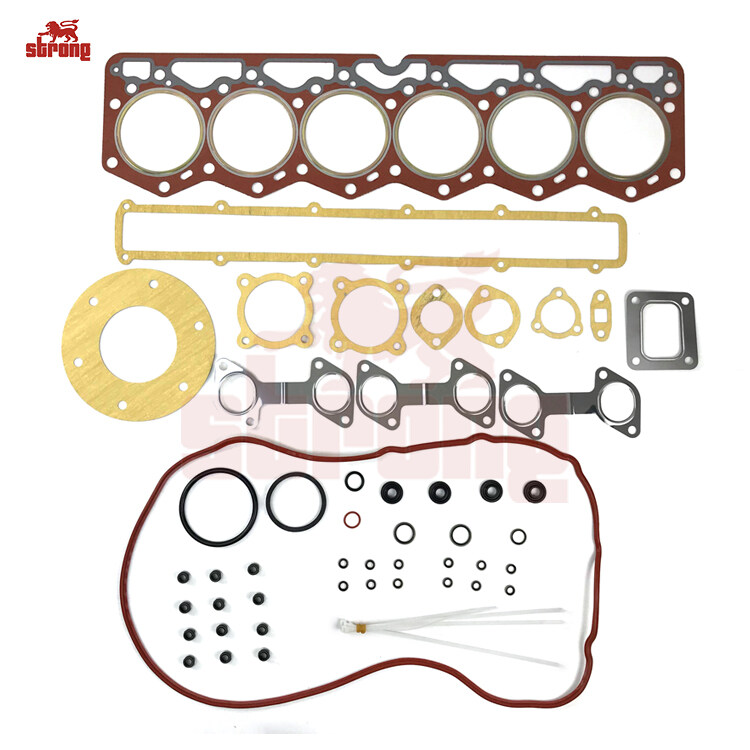

S6D125 Diesel Engine Main Bearing

The S6D125 engine main bearing is a critical component of the S6D125 engine, which is typically found in various heavy equipment and industrial applications, especially in machinery from Komatsu. Main bearings are an essential part of the engine's bottom end and are responsible for supporting and maintaining the proper alignment of the engine's crankshaft.

S6D125 Diesel Engine Main Bearing Product Description:

Engine bearings do many things. They support moving parts like crankshafts and connecting rods, but they also play a role in determining an engine's oil pressure and protect the crankshaft from being damaged by micron-sized particles.

Improper bearing selection and/or sizing can result in problems ranging from poor oil consumption to all-out, catastrophic engine failure. Ensuring that the correct bearing size, and therefore proper clearances are selected, can be accomplished relatively easily and for surprisingly little money.

The diesel engine bearing is a critical component that is designed with advanced manufacturing technology and precision measurement equipment. Its unique shape and size are carefully crafted to ensure a perfect fit with other parts of the diesel engine, allowing for accurate collaboration and optimal performance. Additionally, the bearing is made from lightweight materials, which reduces its volume and weight, making it an economical choice for lighting diesel oil.

The Lightweight Design Improve the Engine Power Density:

The main bearing adopts a lightweight design, which reduces the overall weight of the engine and improves its power density and fuel economy. This design feature is achieved through the use of advanced materials and manufacturing techniques that allow for the creation of a strong and durable main bearing that is also lightweight. By reducing the weight of the engine, the diesel engine can achieve higher power output and better fuel efficiency, making it an ideal choice for a wide range of applications. Additionally, the lightweight design of the main bearing helps to reduce the overall size and complexity of the engine, making it easier to install and maintain.

The Advanced Material and Manufacture Craftsmanship Better Fit Green Environment:

The main bearing is designed with advanced materials and manufacturing techniques that help to reduce the engine’s energy consumption and emissions, making it an environmentally friendly and energy-efficient choice. The use of advanced materials, such as high-strength alloys and composites, allows for the creation of a main bearing that is both strong and lightweight, reducing the overall weight of the engine and improving its fuel efficiency. Additionally, the advanced manufacturing techniques used in the production of the main bearing help to ensure that it is made to the highest standards of quality and precision, further improving the engine’s performance and reducing its environmental impact. By reducing energy consumption and emissions, the main bearing meets the modern requirements for energy efficiency and environmental sustainability, making it an ideal choice for a wide range of applications.

S6D125 Diesel Engine Main Bearing Product Parameter:

|

Product Name |

Engine Bearing |

|

Application |

Engineering Machinery Engine |

|

Engine Number |

S6D125 |

|

Size |

STD |

|

OEM Number |

6150-21-8010 |

|

Condition |

100% Brand-new |

|

Size |

STD 0.25 0.50 0.75 1.00 |

|

Material |

Copper |

|

Warranty |

6 Months |

|

Payment Way |

T/T, L/C, Paypal, Western Union, UPS |

|

Car Model |

KOMATSU |

|

Packing |

Neutral Packing |

The features and functions of the S6D125 engine main bearing:

-

Material and Construction: Main bearings are typically made from strong and durable materials, such as steel or aluminum alloys, to withstand the extreme loads, pressures, and temperatures associated with engine operation. They are often designed for specific applications and engine models.

-

Supporting the Crankshaft: Main bearings serve as a crucial interface between the engine block and the crankshaft. They support the crankshaft's weight and provide a low-friction surface for the crankshaft to rotate on.

-

Alignment: Main bearings help maintain the precise alignment of the crankshaft within the engine block. This is critical for ensuring that the engine's moving parts, such as the pistons and connecting rods, operate smoothly and efficiently.

-

Load Distribution: Main bearings evenly distribute the loads and forces generated during the engine's operation, preventing uneven wear on the crankshaft journals and the bearings themselves.

-

Lubrication: Main bearings are designed with grooves or channels that allow engine oil to flow through and provide lubrication to reduce friction and prevent excessive heat buildup. Proper lubrication is essential for preventing bearing wear and engine damage.

-

Heat Dissipation: Main bearings are engineered to dissipate heat generated by the friction between the crankshaft and bearing surfaces. Overheating can lead to bearing damage and engine failure.

Product Types:

Plain, or sleeve, bearings are the most common type used today. Such bearings come in half-shell-shaped pairs that, when matched together at their parting faces, encompass a crankshaft's main journals and rod journals 360 degrees.

Product Material:

Bearings can be made of a variety of different materials and always consist of a soft and a hard material cast, sintered or bonded to one another. Bearing material choice affects factors such as engine longevity, corrosion resistance and the ability to withstand fatigue and occasional detonation through increased load capacities.

Babbitt, copper-lead alloy and aluminum are a few of the most widely used surface-coating materials of recent years. No matter which material is selected, all three are coated on top of a low-carbon, hardened steel backing-the material that makes up a good portion of the bearing shell, gives it its shape and receives the brunt of the load. Such coatings are applied in approximately 0.01-0.02-inch layers.

Babbitt is just about the oldest bearing surface coating and is probably the least used today. Its most useful trait is its high rate of embedability, a situation in which the bearings are more likely to pick up foreign particles, keeping them from scoring the crankshaft or floating in the oil film. The particles simply make their way around the bearing until they are completely covered by the material.

Pull an old bearing out of an engine and you're sure to find speckles of particles thanks to the bearing's embedability characteristics. Of course, religious oil changes make a bearing's embedability less of an issue. Babbitt bearings also have a higher rate of conformity, which lends itself well to nitro and alcohol engines with extreme cylinder pressures.

Copper-lead alloy bearings on the other hand are highly resistant to fatigue and extremely durable-not so much for the nitro engine but perfect for the typical race engine and most any street engine. Such bearings consist of a sponge-like layer of copper interspersed with lead particles. This combination allows for copper's strength and lead's embedability properties.

Finally, aluminum bearings share many of the same characteristics with copper-lead alloy bearings but are even more resistant to corrosion. Aluminum bearings rank lower in deformability and embedability but that's becoming less of an issue with today's more sophisticated filtration systems.

The aftermarket has also concocted a few different surface coatings including various alloys designed for even greater corrosion resistance and strength and there are certainly other less popular materials from years back such as tin-based and lead-based alloys as well as others that were cast directly as part of the connecting rods.

Our Advantages

1.Free samples,fast delivery

2.Small order accepted

3.OEM service welcome

4.Customers' drawing or samples accepted

5.Excellent and high quality control,high speed,low noise,long life

6.Passed ISO9001-2000 & TS16949/ISO14001

7.Our price can according to the customers' requirements and your market demand.